How to process the tooling board?

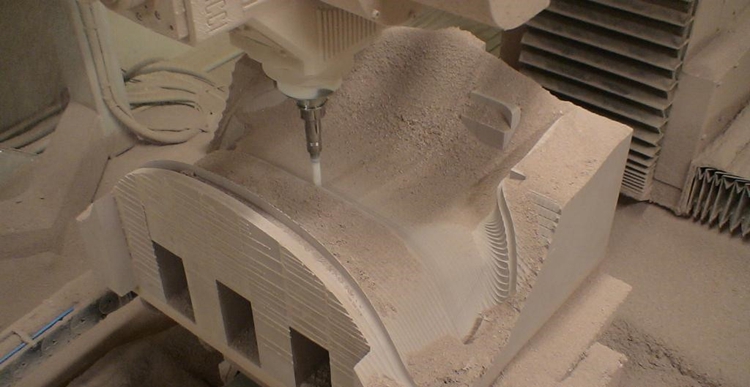

The first step is to fix the tooling board on the workbench and use tools such as pressure plates. It is not necessary to use adsorption, because the adsorption effect of the plane of the tooling board may not be good.

The second step is to prepare the tool. The tool material that is often used in the tooling board is cemented carbide. Cemented carbide tools are further divided into solid carbide for the shank and coated carbide for the blade. The former is more expensive, while the latter is more cost-effective. Currently, the applications of different enterprises are different.

The third step is to set the processing parameters in the programming software. Generally, the spindle speed of the processing tooling board is between 10000-20000 rpm, the feed is between 8000-10000mm/min, and the cutting amount is between 0-15mm.

The fourth step, set the coordinate origin, set the tooling board, and start the execution program button.

The fifth step, because the toughness of the tooling board is relatively brittle when feeding, try to use a circular arc feed knife. If a straight line feed is used, the tool plate is easy to crack.

The sixth step is the treatment of dust during processing. The extremely tiny dust generated by tooling board during processing will have an impact on the surrounding environment. At this time, the vacuuming device should be activated.

The seventh step is product inspection. For the processed workpiece, each unit performs three-coordinate or photographic measurement of the product according to different needs.