DQ Tooling Board Enables Precision Automotive Model Making

DQ Tooling Board Enables Precision Automotive Model Making

Introduction:

DQ Tooling Board has established itself as a leading supplier of high-quality tooling boards for various industries. This case study focuses on a client in the automotive industry who used DQ Tooling Board's products to create highly precise and accurate models of their new car designs.

Background:

The client needed to create a prototype model of a new car design that required a high level of precision and accuracy. They had previously used traditional tooling materials, such as wood and foam, but found that these materials did not provide the necessary level of precision and accuracy.

Solution:

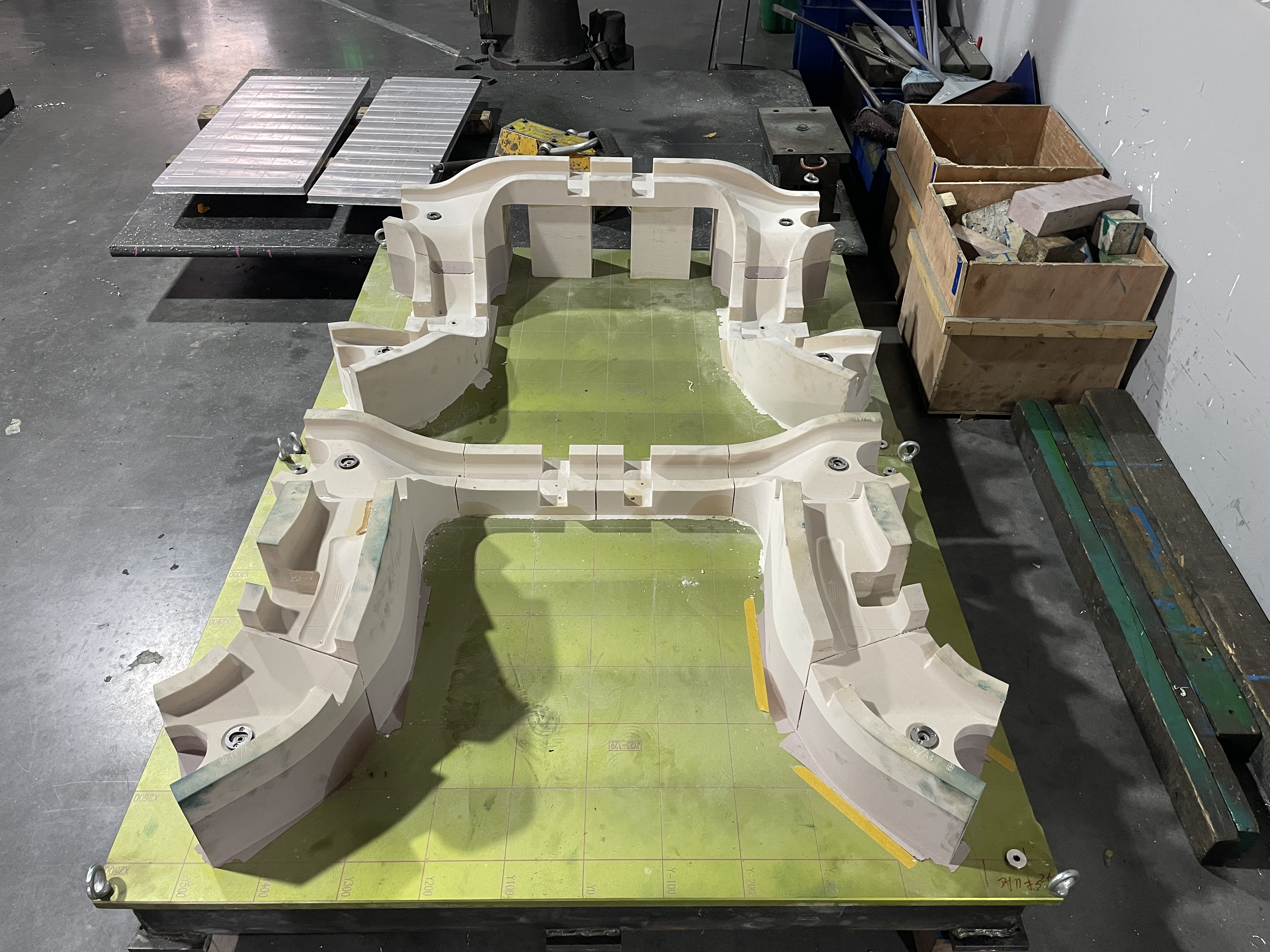

DQ Tooling Board recommended their Premium Epoxy Tooling Board, which is specifically designed for model making and offers exceptional dimensional stability, surface finish, and accuracy. The client was initially hesitant due to the higher cost of the material compared to traditional materials, but DQ Tooling Board provided samples and technical support to demonstrate the benefits of the Premium Epoxy Tooling Board.

Results:

The client was able to create highly precise and accurate models using the Premium Epoxy Tooling Board, which allowed them to better visualize and refine the design of the car. The dimensional stability of the tooling board ensured that the models remained accurate over time, even with frequent handling and modifications. The surface finish of the board was also exceptional, providing a smooth and high-quality finish to the model. The client was impressed with the results and has since continued to use DQ Tooling Board for their model making needs.