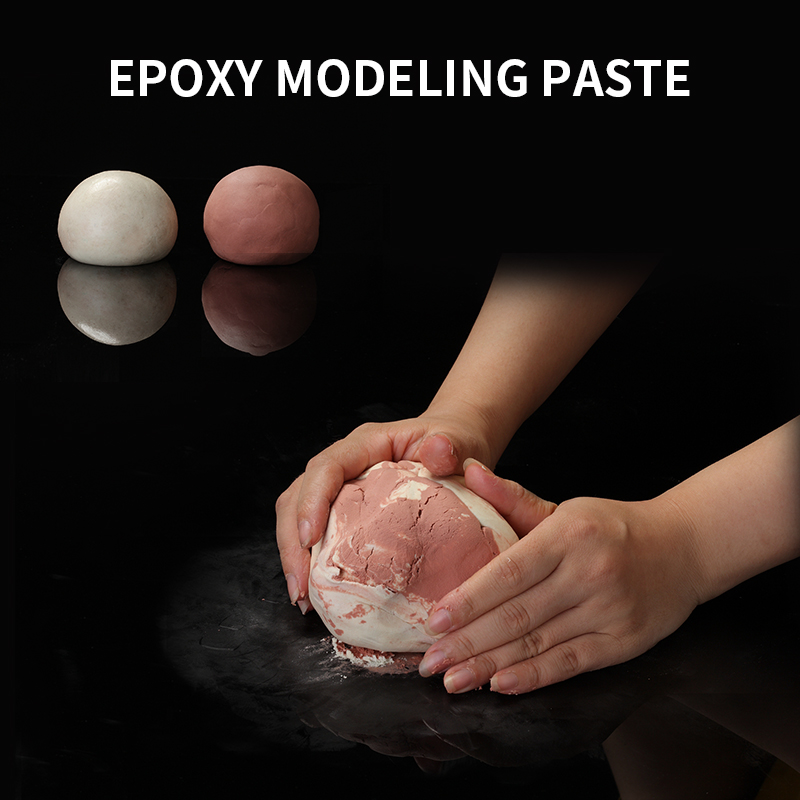

DQ1000 Epoxy Modeling Paste For Master model Manufacturing Sample

Brand DQ-TOOL

Product origin CHINA

Delivery time 2 weeks

Supply capacity 2000 KGS

Material EPOXY

Density (kg/cm³) 1.0-1.35 g/cm³

Hardness (Shore D) 65-75 Shore D

COMPRESSIVE STRENGTH (Mpa) 55-65 Mpa

THERMAL DEFORMATION TEMP (℃) 60-70 ℃

TENSILE STRENGTH (Mpa) -

● Brown epoxy laminating resin

● Density:1.0g/cm³ or 62 lb./ft.³

● Low specific gravity

● Easy to form

Download

DESCRIPTION:

DQ Epoxy Laminating Resin is a versatile material with three different densities ranging from 0.5 to 1.0g/cm³, making it ideal for various applications. It has a low specific gravity and is easy to form, making it easy to use. This material mixes easily, making it an excellent choice for master models, manufacturing samples, and automotive design modeling. Its properties make it a great option for those looking for a material that is easy to work with and produces excellent results.

● Low specific gravity

APPLICATION:

● Master model

● Manufacturing sample

● Automotive design modeling

PHYSICAL PROPERTIES:

Type | Color | Mix ratio | Pot life | Gel time | Cured time |

DQ 1000A (resin) | Light Brown | 1 | 10-20 Min | 40 Min | 24 Hour |

DQ 1000B (hardener) | White | 1 |

CURED PARAMETER:

Type | DQ 1000 A/B |

Color | Brown |

Density(ISO 1183) | 1.0-1.05g/cm³ 62 lb./ft.3 |

Cured Hardness (ISO 868) | 70-75shore D |

Coefficient of thermal expansion (ISO 11359) | 55-60 x 10-6K-1 |

Hot deformation temperature(ISO 75) | 60-65℃ |

Compressive strength (ISO 604) | 60-65 MPa |

Specifications | 10kg/barrel |

PROCESSING CONDITIONS:

The mixing is carried out by hand for quantities below 1 kg and for larger quantities with a planetary mixer.

STORAGE :

The product has a shelf life of six months and should be placed in a dry, cool place below 30℃. Unused products must be stored in a sealed condition.